Leading Chinese Factory Revolutionizes Global Standards in Lighting Light Manufacturing

In an era where energy efficiency and sustainable practices are paramount, the role of innovative manufacturing in the lighting industry has never been more critical. A leading Chinese factory is at the forefront of this transformation, setting new global standards in the production of Lighting Light. With cutting-edge technology and a commitment to environmentally friendly processes, this factory is revolutionizing the way we approach lighting solutions. By emphasizing quality, efficiency, and sustainability, it not only caters to the demands of the modern market but also leads the charge in redefining industry benchmarks. As businesses and consumers alike seek eco-friendly alternatives, this factory stands as a beacon of progress, pushing the boundaries of what is possible in lighting manufacturing. This blog delves into the factory's pioneering techniques, its impact on the global lighting landscape, and its vision for a brighter, more sustainable future.

Innovative Technologies Driving China's Lighting Manufacturing Forward

In the rapidly evolving world of manufacturing, one Chinese factory stands out by spearheading a revolution in lighting technology. By embracing innovative technologies, this factory not only enhances its production capabilities but also sets new global standards in the lighting industry. Utilizing advanced automation and smart manufacturing processes, it has dramatically increased efficiency, reducing waste and production time while maintaining exceptional quality. These breakthroughs underscore the factory's commitment to sustainability and cost-effectiveness, which are increasingly crucial in today's competitive market.

Moreover, the integration of IoT (Internet of Things) and AI (Artificial Intelligence) has allowed for real-time monitoring and predictive maintenance, further optimizing the manufacturing process. This forward-thinking approach not only elevates product quality but also enables rapid adaptation to market trends and consumer demands. By investing in research and development, this Chinese lighting manufacturer is paving the way for smart lighting solutions that enhance user experience and energy efficiency, positioning itself as a leader in an industry poised for exponential growth.

Distribution of Innovative Technologies in China's Lighting Manufacturing

Impact of LED Adoption on Global Lighting Industry Standards

The global lighting industry is witnessing a transformative shift, largely driven by the rapid adoption of LED technology. This innovation is not just enhancing energy efficiency but is also setting new benchmarks for quality and sustainability. More manufacturers are now following these rigorous standards, which emphasize not only performance but also eco-friendly practices. The proliferation of LED lighting has led to a standardized approach, enabling businesses worldwide to meet consumer demands for longer-lasting, energy-efficient products.

Tip: When considering an upgrade to LED lighting, look for products that meet international energy efficiency standards. This ensures you’re investing in quality while reducing your carbon footprint.

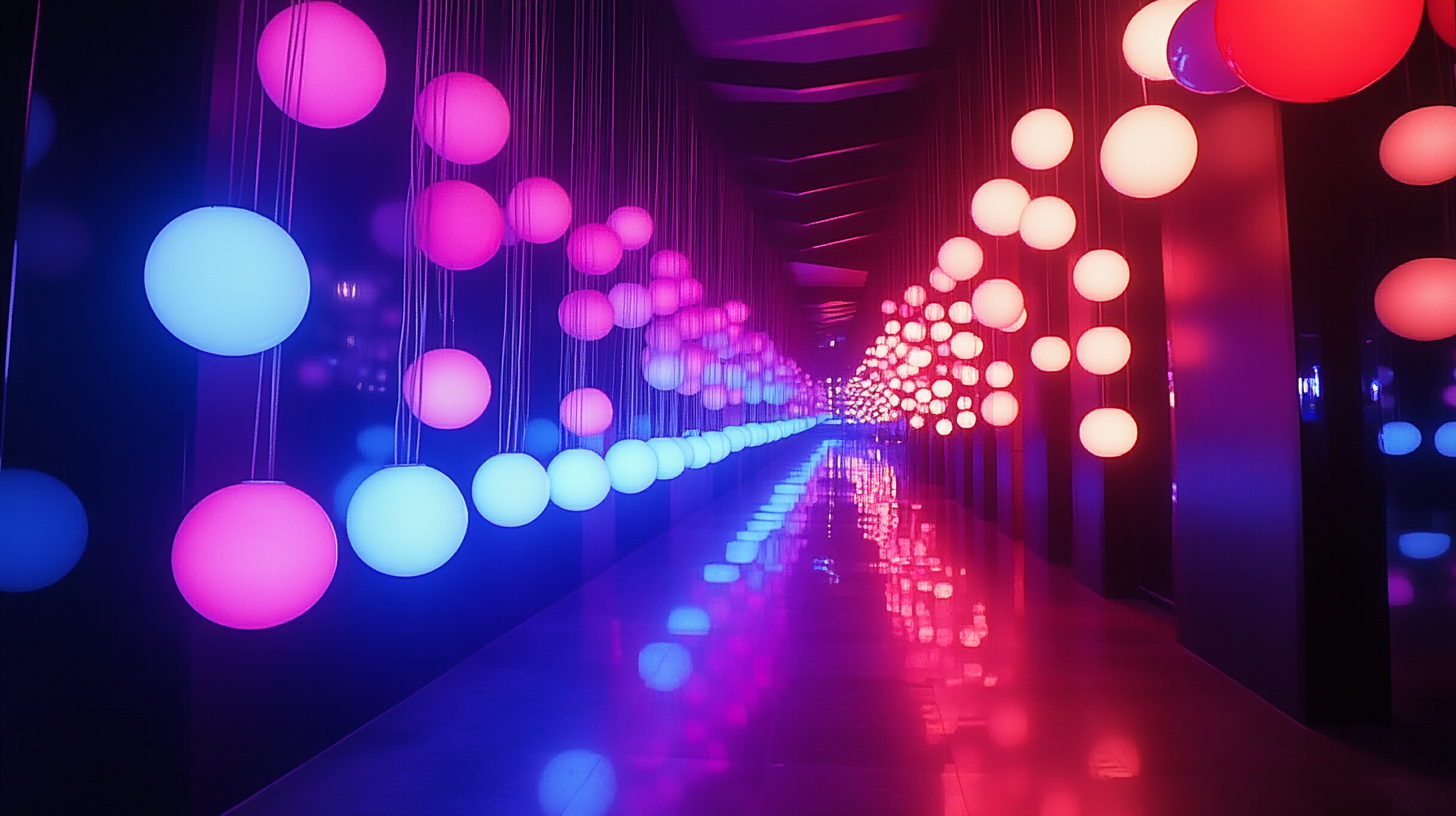

Moreover, the rise of smart lighting systems integrated with LED technology is pushing manufacturers to innovate continually. Features such as adjustable brightness and remote control capabilities are making lighting more customizable. This leads to a more personalized user experience and reinforces the necessity for manufacturing standards that keep pace with technological advancements.

Tip: Always check for certifications like Energy Star or equivalent when purchasing LED products. These certifications guarantee that the products undergo rigorous testing for quality and performance.

Sustainability Practices Transforming Light Manufacturing in China

In the rapidly evolving landscape of light manufacturing, a leading Chinese factory is setting new benchmarks through its commitment to sustainability practices. This factory has embraced innovative technologies that not only enhance the production process but also significantly reduce environmental impact. With a focus on energy-efficient production techniques, the facility has implemented advanced machinery that minimizes waste while optimizing energy consumption, positioning itself as a leader in eco-friendly manufacturing.

Moreover, the factory's dedication to sustainability goes beyond just energy savings. It actively sources raw materials from certified sustainable suppliers, ensuring that its supply chain adheres to environmental standards. By integrating circular economy principles, the factory is not only reducing its carbon footprint but also paving the way for a more responsible approach to light manufacturing in China. These efforts are not merely in response to global pressure but reflect a genuine shift towards more conscientious business practices, demonstrating that profitability and sustainability can indeed go hand in hand in the quest for excellence in the lighting industry.

Market Trends: China's Influence on Global Lighting Product Pricing

The global lighting market is experiencing significant shifts, particularly influenced by China’s manufacturing prowess. The global lighting controls market is projected to witness robust growth, climbing from an estimated $32.26 billion in 2023 to approximately $124.45 billion by 2032, indicating a strong CAGR that reflects the rising demand for energy-efficient solutions. This trend underscores the crucial role China plays in shaping pricing strategies and product availability in the global market.

Moreover, as the demand for LED technology continues to rise, particularly in renovations and upgrades, the LED general lighting market is set for a rebound, driven by modernization efforts across various sectors. Industry reports predict a substantial recovery as consumers increasingly opt for energy-efficient products. The high-end lighting market is also expanding, expected to value around $20.26 billion in 2024 with a notable growth trajectory projected through the next decade. This growth further emphasizes the shift towards sophistication and efficiency in lighting solutions, showcasing how Chinese manufacturing is not just influencing pricing but also the overall standards and trends in the global lighting industry.

Quality Assurance: How Chinese Factories Meet International Standards

In the competitive landscape of global lighting manufacturing, Chinese factories are setting new benchmarks for quality assurance that meet and often exceed international standards. By implementing stringent quality control processes and embracing advanced technologies, these factories have established themselves as leaders in the industry. A key aspect of their success is the rigorous testing protocols they adhere to during production, ensuring that every product not only meets domestic requirements but also complies with international regulations.

Moreover, collaboration with foreign entities has allowed these Chinese manufacturers to adopt best practices and innovative solutions from around the world. Continuous employee training programs focus on the latest manufacturing techniques and quality assurance methodologies, enhancing overall productivity and product integrity. This commitment to maintaining high standards is evident in their certifications, which include ISO quality management systems and other relevant industry accreditations. As a result, Chinese factories are not just transforming their operations but are also elevating global lighting manufacturing standards.